The pandemic situation has given people a lot of free time, and some people have chosen to go extreme with this time. A YouTuber, who runs a channel called “Electric SuperCar”, had started working on transforming a K1 kit car into an electric supercar back in 2019. He utilized the spare time during the lockdown and built an electric car capable of accelerating from 0-60 mph (96.5 kph) in just 2.3 seconds.

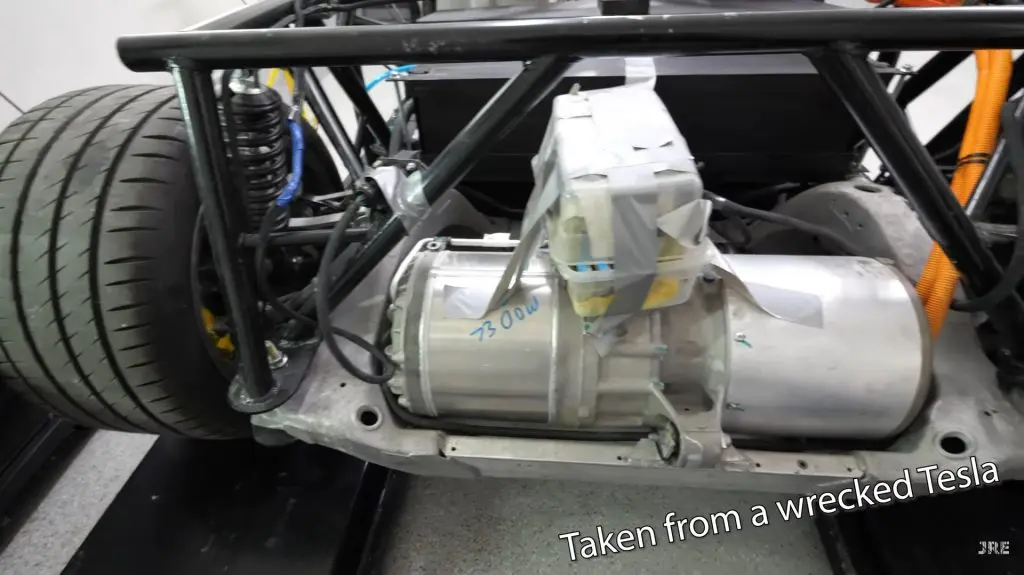

He used an electric motor obtained from a wrecked Tesla in his car. This motor gets its power from LG Chem batteries modules and uses a motor controller to deliver the optimum power to the wheels. Another YouTuber Jerry from “Jerry Rig Everything” decided to interview this guy and understand the process behind building an electric supercar in your garage. So, let’s see how to build an electric car (kind of!).

Fundamentals of the DIY Electric Supercar

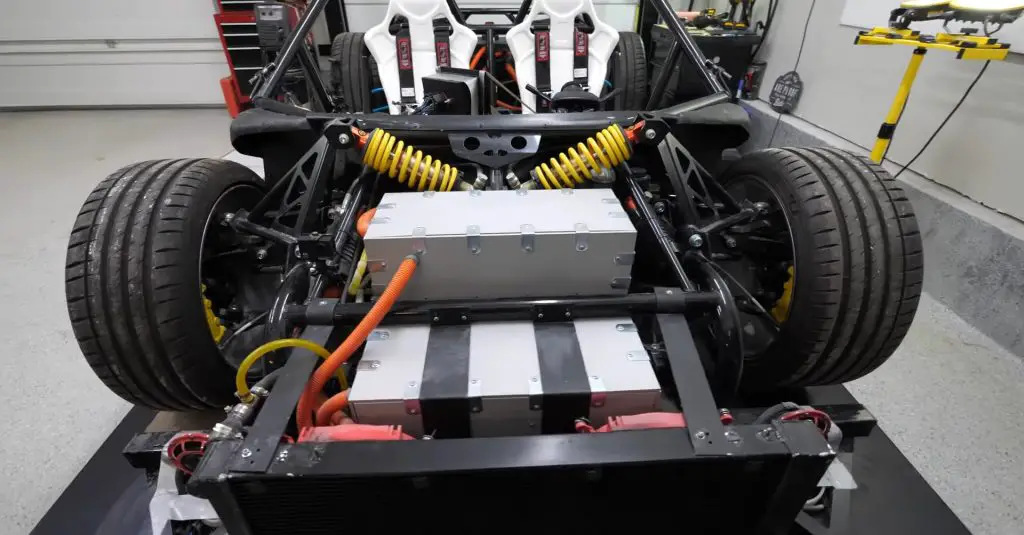

The electric car contains a 620 kW electric motor and a motor controller which is the one Tesla uses in its cars as well. There are a total of 12 LG Chem battery modules, which provide the high voltage (HV) system with 400 volts. There is also a 12V battery that powers the low voltage (LV) system, i.e., headlights, starter button, turn signals. He went old-school with the low voltage system by using relays.

The motor controller essentially sends CAN signals to the motor, telling it how much power is to be generated and sent to the wheels. He has divided the 12 battery modules into two battery packs of 6 modules each. One pack is in the front part of the chassis, while the other is in the rear. A high voltage harness connects the two battery packs to the motor. The front radiator cools down the battery pack using a liquid-cooled system.

The chassis of the vehicle comes from a Honda Accord drivetrain, and he modified it to fit some of the components. There is a charging port in the rear part of the car and the onboard charger near the 12V battery houses the AC-DC converter. There is also a DC-DC converter, which provides power to the LV system. The rotors and suspension come from a Tesla car, but the wheels are from a different car. They are 19″ wheels with 325 mm width.

Each battery module weighs around 18 kg, so the total weight of the battery packs is around 220 kg in all.

Getting On The Move

Switching on the starter button switches the controller on, which then turns on the contactors for the HV system. The only sound audible is from the coolant pump in the radiator. Of course, being a work-in-progress project, some safety elements are missing, like the windshield and doors. But the car does have seat belts, so that’s good news.

The Driving Experience

Of course, since this is not a road-legal car (yet), he hasn’t been able to test it out to the extreme. He does run it around an old parking lot near his house, and he took Jerry there for a spin. Since the tires on this car aren’t the optimal type for this kind of car, he’s facing issues with the traction control. The power supplied by the motor is too much for the tires to handle, which means they are getting spun a lot faster than they can actually get grip on. The result – a lot of wheel spin and not much high-speed acceleration.

Currently, the motor is spinning at just 340 kW of power, but the tires cannot transform that much power into on-track performance. It gives out a rough estimate of 620 horsepower, which is impressive for a DIY car. And even with the wrong set of tires and cold weather conditions, it can still accelerate from 0-60 mph in 2.3 seconds. That is impressive. Even with the traction loss, it is able to accelerate as quickly as a 2020 Tesla Model S Performance. Yes, the vehicle is much lighter, but it’s still impressive.

Of course, by installing wheel speed sensors on the tires, he’ll be able to solve the traction problem. And obviously, he can use tires that are better suited.

The Path to Building This Car

He says the most important thing you’ll need is a K1 kit and perseverance. It isn’t easy to build an entire car by yourself. You have to think about the chassis, the steering, brakes, electronics and whatnot. But if you have the passion to build, you can complete it.

Talking about the current project, he says that the body panels have been manufactured using glass fibre. They need to fit onto the chassis in order to give it a more car-like feel to it. Talking about the future, he says that he’d love to build an entire vehicle from scratch, frame and everything. He said that one of the toughest parts of building this car was getting components to fit in places that weren’t designed for them. So if you start the car from zero, you can think about the packaging of components as well.

You can view the entire video over here: