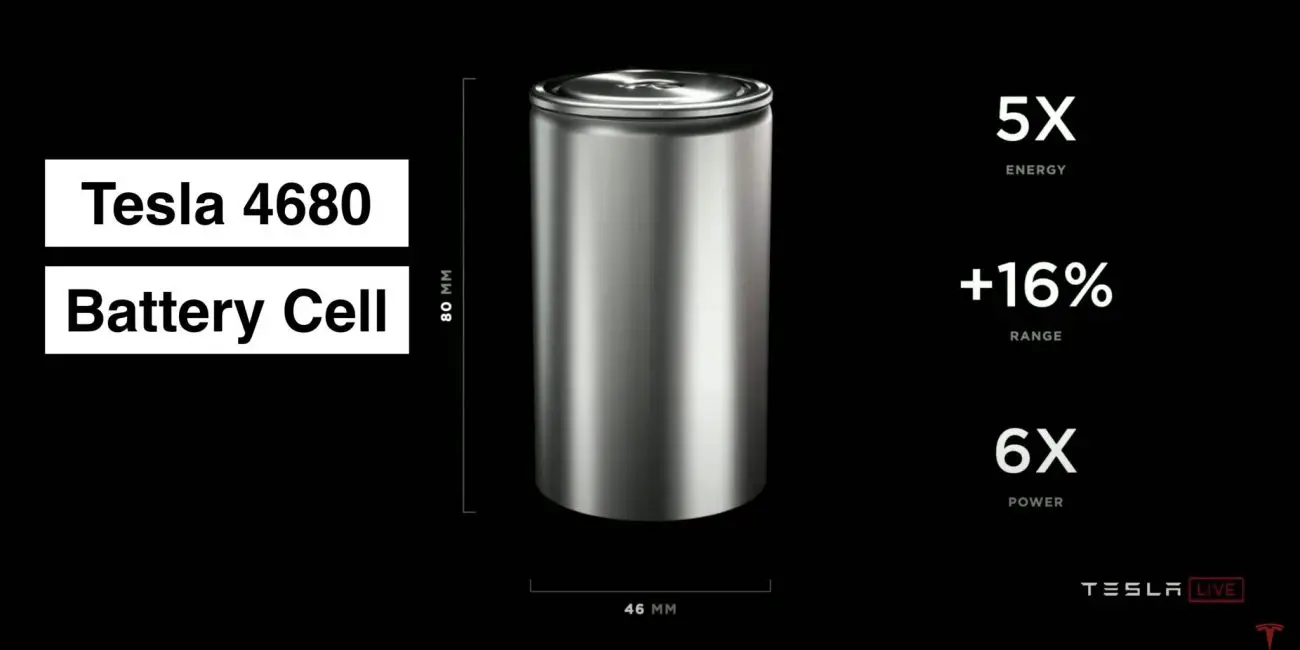

In September 2020, the electric vehicle industry was abuzz with anticipation as Tesla hosted its much-awaited “Battery Day.” During this landmark event, Tesla CEO Elon Musk took to the stage to unveil what was touted as a game-changing innovation: the 4680 battery cell. This new battery was heralded as the solution to a multitude of challenges that have long plagued electric vehicles.

From significantly extending driving range to drastically reducing manufacturing costs and enabling mass production, the 4680 battery was set to revolutionize not just Tesla’s future, but the entire landscape of electric mobility.

Fast forward to three years later, and the picture looks quite different. While Tesla has made strides in various aspects of its business, the lofty promises surrounding the 4680 battery remain largely unfulfilled. Only a specific version of the Model Y is currently equipped with this new battery, and the benefits it offers are not as groundbreaking as initially promised. This gap between the high expectations set during Battery Day and the current reality poses questions about the challenges Tesla is facing in bringing this transformative technology to market.

Table of Contents

Tesla 4680 Battery Update

One of the most enticing promises made during Tesla Battery Day was the significant increase in driving range that the 4680 battery would offer. A longer range would not only make electric vehicles more appealing to consumers but also alleviate range anxiety, a common concern among potential EV buyers.

Another cornerstone of the 4680 battery’s appeal was its potential to drastically reduce manufacturing costs. By innovating the battery design and production process, Tesla aimed to make electric vehicles more affordable, thereby accelerating the transition to sustainable transportation.

The 4680 battery was not just about individual vehicle improvements, it was about scaling these benefits across millions of vehicles. Tesla’s vision was to ramp up production to unprecedented levels, making electric vehicles accessible to a broader audience and taking a significant step toward a sustainable future.

Removal of the 4680 Battery from Tesla Model Y

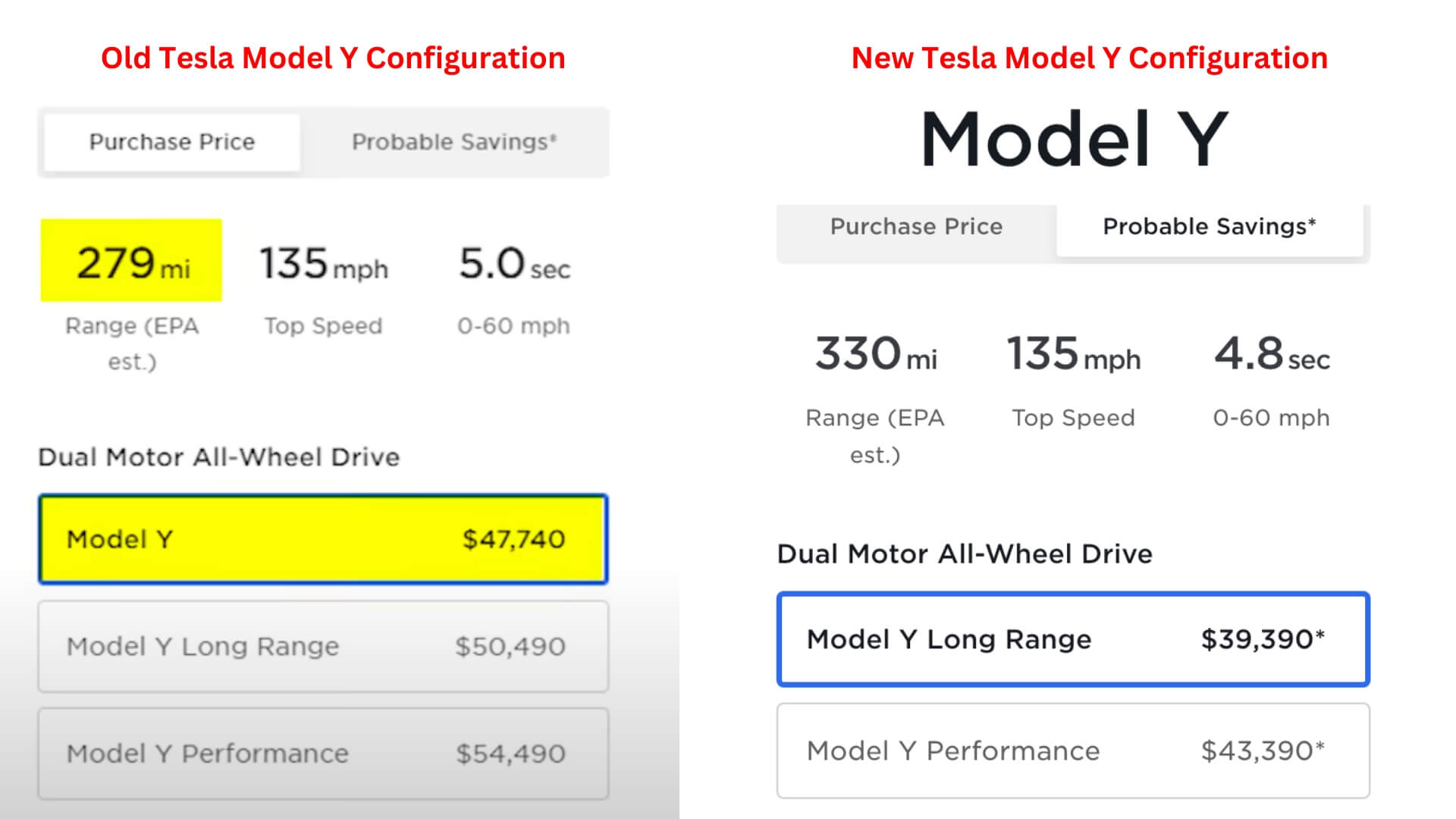

Despite the grand promises, the 4680 battery was only available in the base Tesla Model Y, but now Tesla has stopped selling the base version. The cheapest Tesla Model Y you can buy is the Long Range Version. This limited rollout has not only raised questions about Tesla’s production capabilities but also about the actual benefits that the new battery brings.

The version of the Model Y equipped with the 4680 battery did not significantly outperform its counterparts in terms of range or cost. In fact, that version offered less range and power than the Long Range Tesla Model Y and only cost about $3,000 less. This discrepancy between what was promised and what has been delivered is a stark reminder that revolutionary technology often faces real-world challenges that can delay or diminish its impact.

Tesla 4680 Battery Production Status

When it comes to the 4680 battery, one of the most glaring issues is the bottleneck in production. Tesla has reached several milestones, but they are far from the numbers needed to make a significant impact on the electric vehicle market. Here are some key production numbers:

- February 18, 2022: Tesla announced the production of 1 million 4680 cells at their pilot line in Fremont, California.

- December 25, 2022: The company achieved a run rate of 868,000 cells in a seven-day period, combining production from both Fremont and Giga Texas.

- June 16, 2023: Tesla announced that they had manufactured 10 million 4680 cells at Giga Texas.

While these numbers may seem impressive at first glance, they fall short when considering the scale at which Tesla aims to operate.

The Gap Between Prediction and Reality

Tesla had set ambitious targets for its 4680 battery production. During Battery Day, the company predicted that Giga Texas would reach an annual production capacity of 100 gigawatt-hours by 2022 and scale up to three terawatt-hours by 2030. However, as of summer 2023, Tesla is nowhere near these goals.

To put it in perspective, the 10 million cells produced at Giga Texas equate to less than one gigawatt-hour of energy storage capacity. Each of the four battery lines at Giga Texas is supposed to have a total capacity of 25 gigawatt-hours per year. So far, Tesla hasn’t even hit 1/25th of one line’s capacity after at least six months of production.

This significant gap between Tesla’s predictions and the actual production numbers raises questions about the company’s ability to meet its own ambitious targets. It also casts doubt on whether Tesla can deliver on the promises of increased range, lower costs, and mass scalability anytime soon.

Tesla 4680 Battery Issues: Technical Challenges

Let’s delve into the technical challenges that Tesla faces in the production of its 4680 battery. From the partial implementation of the dry electrode process to issues with material choices, these challenges offer insights into why Tesla has struggled to meet its ambitious goals.

The Dry Electrode Process

One of the key innovations that Tesla introduced with the 4680 battery is the “dry electrode process.” Unlike the traditional “wet process,” which uses liquid solvents to bind the active material to the metal foil in the battery, the dry process aims to eliminate the need for these solvents. By doing so, Tesla hoped to reduce manufacturing costs and complexity.

As of now, Tesla has only successfully implemented the dry electrode process for the anode side of the 4680 battery. The cathode side still relies on the traditional wet process. This partial implementation means that Tesla has not yet realized the full cost-saving potential that the dry process promises.

Issues with the Dry Process

The dry process requires high pressure to bind the active material to the metal foil, exerting a lot of shearing force on the mixture. This force can damage the active material, leading to inconsistencies in the battery’s performance.

Achieving consistent results with the dry process has proven to be a significant challenge. The process often results in a thicker electrode with more binder particles, reducing the battery’s energy density. These inconsistencies have led to increased production costs and delays.

Material Choices

Tesla has opted for a pure graphite anode in the 4680 battery, deviating from its previous batteries, which used a mix of graphite and silicon. The use of pure graphite likely stems from the challenges associated with implementing the dry process with silicon, which is more susceptible to damage under high pressure.

The absence of silicon in the 4680’s anode is noteworthy because silicon generally allows for higher energy density and faster charging rates. However, it seems that the difficulties in implementing the dry process with silicon have led Tesla to opt for pure graphite instead.

Statements from Tesla’s March 2023 Investor Day

Despite the challenges and bottlenecks, Tesla has not thrown in the towel. During Tesla’s March 2023 Investor Day, Drew Baglino, Tesla’s Senior VP of Powertrain Development, provided valuable insights into the company’s ongoing efforts. He emphasized that they haven’t “stalled out yet on the rate of progress,” indicating that work is actively underway on both the anode and cathode sides of the 4680 battery.

Tesla’s Ongoing Efforts to Solve the Challenges

Tesla is fully aware of the issues plaguing the 4680 battery and is committed to resolving them. The company is likely focusing on several key areas:

- Improving the Dry Electrode Process: Given the partial success in implementing the dry process for the anode, Tesla is likely working on perfecting this technology for the cathode side as well.

- Material Innovations: Tesla may be exploring alternative materials or combinations that can withstand the shearing forces in the dry process, aiming for a more consistent and cost-effective production.

- Scaling Production: Tesla continues to invest in its production facilities, like Giga Texas, to increase the production rate of the 4680 cells. Achieving economies of scale is crucial for reducing costs and making the battery more accessible.

- Quality Control: With the inconsistencies in the dry process, Tesla is likely focusing on quality control measures to ensure that each 4680 cell meets the company’s high standards.

- Sustainability Goals: Tesla’s ambitions are not just about market leadership; they are also about advancing the global transition to sustainable energy. The 4680 battery plays a critical role in this vision, and Tesla is keen on making it a success.

Conclusion

Tesla’s journey with the 4680 battery has been a rollercoaster of high expectations and sobering realities. From production bottlenecks to technical challenges like the partial implementation of the dry electrode process and material choices, Tesla has encountered a series of hurdles. These challenges have not only delayed the mass rollout of the 4680 battery but have also raised questions about whether Tesla can deliver on its ambitious promises of increased range, lower costs, and scalability.

Despite these setbacks, Tesla’s commitment to overcoming these challenges remains steadfast. The company’s ongoing research and development, as evidenced by statements from senior leadership, indicate that Tesla is far from giving up on the 4680 battery. They are actively working on improving the dry electrode process, exploring alternative materials, and ramping up production capabilities. Tesla’s unwavering focus on innovation and sustainability suggests that they are still very much invested in making the 4680 battery a cornerstone of the electric vehicle revolution.

NAILED IT!! I have made numerous comments that the Tesla 4680 battery was a piece of junk. Another act of Elon Musk burning Tesla buyers. Good luck getting warranty work from mister mini me Truump Musk.