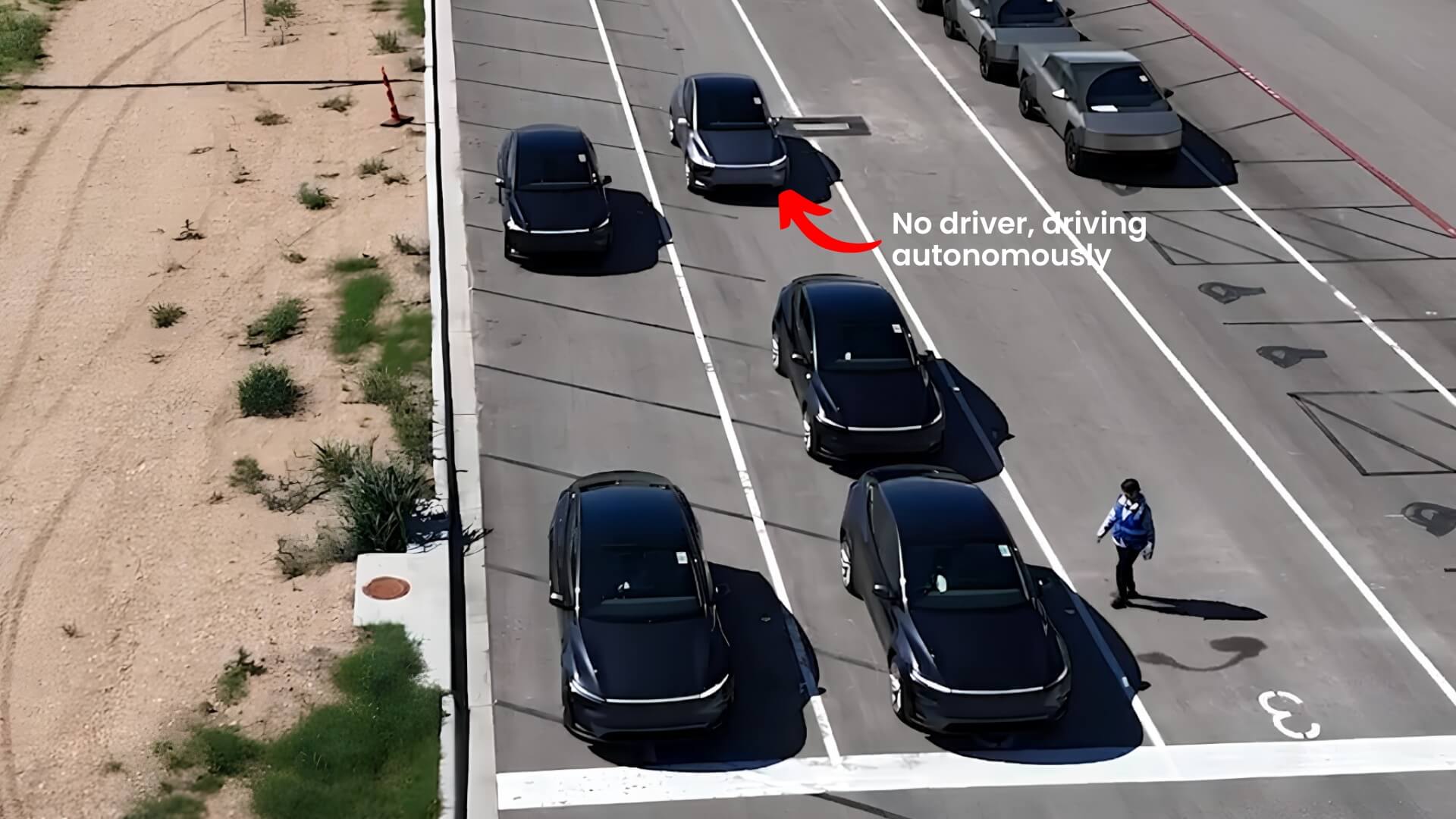

In a big boost for autonomous driving technology, Tesla has extended its Full Self-Driving (FSD) Unsupervised abilities to its Giga Texas manufacturing facility. Beginning today, all new Model Y and Cybertruck vehicles coming off the assembly line are driving themselves out of the end of the assembly line and to the west outbound lot autonomously, completely without a human even looking after them.

This is a big moment for Tesla: the operational capabilities and real-world usage of its FSD software in a very controlled but impactful environment.

Earlier in this year, a similar deployment was performed at the Fremont factory, where vehicles have been driving autonomously from the production line to delivery loading bays for over two months. The success at Fremont set the stage for a wider rollout, and now Giga Texas comes on board, the cutting edge of Tesla’s autonomous manufacturing process.

Factory Autonomy in Action

At Giga Texas, Tesla’s factory premises have become an actual proving ground for FSD. Onlookers have seen a steady stream of brand new Model Ys and Cybertrucks rolling off the assembly line and peeling off on their own. These vehicles drive through factory lanes, turn, and place themselves at the outbound logistics area—all without a person in the driver’s seat or monitoring the situation.

This autonomous handoff represents a paradigm change in factory operations, as the manual driving of each vehicle is reduced, and the overall throughput and safety in logistics can be improved. Although the distance may seem short, the implications are profound: by accomplishing the task in a complex, real-world navigation setting without human fallback, Tesla is showing that FSD has its act together.

Breaking Giga Texas News! starting today, new vehicles (Model Ys & @Cybertruck are moving fully autonomously from the factory to the west outbound lot and without human supervisors!

I saw this happening constantly, with Model Ys exiting and immediately driving away on their own… pic.twitter.com/LOAaao99OL

— Joe Tegtmeyer 🚀 🤠🛸😎 (@JoeTegtmeyer) April 7, 2025

Why This Matters

Tesla’s introduction of FSD Unsupervised into the production environment is more than just a showcase – it’s strong proof of concept for the company’s vision for autonomy. Unlike manufactured demos or city streets, factory environments are three-dimensional and limitless, with people, machines in motion, one constant thing: they contain Workers, Equipment, and, more specifically, order. For FSD to function effectively, it has to be making rapid and reliable decisions under real-time input from its sensor suite and neural networks.

By getting to this level of self-sufficiency within its own factories, Tesla is saving operational costs and streamlining the supply of vehicles while also showing the scalability and the flexibility of its self-driving capabilities. It also lays the groundwork for wider usage in public applications as Tesla continues towards achieving full autonomy on public roads.

Tesla’s FSD system has been in continuous development, with incremental improvements being rolled out to customers and in beta programs for years. The freedom to operate without supervision within a production environment shows that Tesla must believe in its reliability.

CEO Elon Musk has for a long time promised that FSD could not only revolutionize consumer driving but manufacturing, delivery, and services of vehicles as well. This development at Giga Texas is a fact of that promises. In essence, the company is preparing its vehicles to be self-sufficient from day zero — leaving the factory production line under their own steam.