The Tesla Battery Day is going to take place on 22nd September in Fremont, California, and it is expected that many prominent announcements might take place. While the Battery Day has been announced for Tesla to unveil battery technology, it is also expected that they are going to unveil some core structural design changes, many of which will be implemented in the Gigafactory Berlin, which is under construction.

Tesla Cars To Undergo Core Structural Design Change

Tesla CEO Elon Musk, who is currently in Berlin overlooking the construction of the Gigafactory, has hinted at some major manufacturing changes that might be brought into effect. It is expected to have the most advanced paint shop, which will be able to provide the Model Y with a variety of multi-layered colors. This will be the first case of a Tesla car having multi-coat options, moving away from Tesla’s initial strategy of offering only white color for improving efficiency on the shop floor. These paint options will eventually be made available in the Fremont and Shanghai plants as well, but it will be harder to implement this in a working factory. Model Y is also the first Tesla car to be made available in China and Europe through local manufacturing.

Tesla Model Y

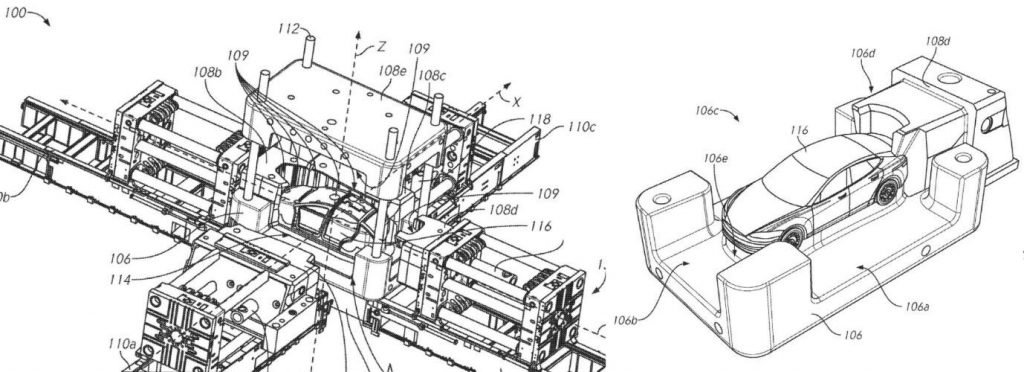

During the first teardown of the Tesla Model Y, it was revealed that the rear end of the electric SUV is made through a beautiful mega casting, which will be a massive manufacturing breakthrough in the industry. The already huge casted parts that Tesla has used are expected to get bigger, as Elon Musk has hinted of combining two large parts in the rear and making one large part. Evidently, this will be made possible through the use of the new casting machines that Tesla has ordered, some of which weigh as high as 5,500 tons.

Tesla Model Y is Tesla’s electric SUV that is a 7-passenger vehicle. A single-charge range of 316 miles (508 kms) and cargo space of 1925 liters. A 0 to 60 mph (96.5 kph) timing of 3.5 seconds and all-weather traction control is made possible through an AWD powertrain consisting of two motors. It also has full self-driving capabilities, bringing the attraction of autonomous vehicles to the fore once again.

The Model Y is supposed to be a revolution in automotive body engineering, with the manufacturing process of casting supposed to be at the forefront of this change. In one of his statements, Musk said that from a manufacturing point of view, 70 parts used in the Tesla Model 3 have been brought down to just 2 in the Model Y. With Fremont being one of the busiest factories for Tesla, these new manufacturing changes are set to be implemented majorly at Berlin, when the newest Gigafactory opens mid-2021.

Tesla Battery Day

In the build-up to the Tesla Battery Day, Elon Musk has hinted at various new upcoming changes that are set to revolutionize Tesla’s future in the industry. With the new paint-shop introducing newer variants of colors in Tesla models, the Model Y will also have an updated body with the casting technology in place.

The Battery Day will also unveil more details about the Berlin Gigafactory, with advanced technologies set to be implemented that will be better than the facilities currently in American factories. Musk was quoted as saying “There’s a bunch of innovative stuff that we will be doing here that we will tell you about in the future. It’s not just a copy of Model Y. It’s actually a radical redesign of the core technology of building a car.”

Thus, it is quite clear that Tesla is looking for a complete reshuffle of the core design of their upcoming cars, starting with the Model Y. They also plan to implement these new designs in the Cybertruck. The Battery Day will unveil more of these core design changes, according to Musk.

This is an image released by Tesla, displaying the giant casting machine constructing the Model Y in almost one piece. Through the use of this, Tesla is looking to automate manufacturing as much as possible, taking steps in the direction of Musk’s vision of having their production plants in the form of an “alien dreadnought”. In this machine, Tesla has introduced its new wiring architecture in the robotic machines, with the aim of increasing automation and reducing material wastage in the manufacturing process. In order to facilitate the automation in the manipulation of the electric harness of their vehicles, Tesla has reduced the length of the harnesses, bringing a total of 3 km of wires in the Model 3 to 1.5 km. With 70% of the parts in the Model Y supposed to be taken from the Model 3, the use of this new architecture is supposed to further improve the manufacturing of the electric SUV.

Elon Musk has been stressing on the shift of Tesla’s image from an automobile company to a manufacturing company, and changes such as this new wiring architecture and the use of revolutionary casting designs will work well in that process. All in all, Musk continues to keep pushing Tesla towards excellence through the progress of automation and establish their position as the industry leader in the electric sector. More to come as September 22nd gets closer.