With almost 1.4 billion cars on the planet over the last century one thing that has been somewhat ignored is the carbon emissions and pollution either low or high but have been continuously added to the environment and now have become a big concern for the environment. Automobiles have a big share of their contribution to the pollution and degradation of the environment.

Combating with this issue more stringent emission standards and norms have been formulated. In this direction we have come so far that we have almost perfected ICE segment extracting the maximum power and mileage from every drop of fuel we use, using hybrid technology, and experimenting with alternative fuels. Also the development in the portable electronic industry unknowingly paved a path for the comeback of the electric vehicles. In the early 1990s, CARB initiated a race for more fuel-efficient and zero-emission vehicles. Many mainstream automakers responded to this with a few models in the short time run. Tesla in 2008 with the Tesla Roadster with a lithium-ion battery cell showed the world what an EV is really capable of, since then automakers have been racing towards making better electric vehicles for all segments.

Having so many advantages over Internal Combustion cars, the electric vehicles have already surpassed them in so many ways and are undergoing tremendous levels of improvements as you are reading this article. They are getting more and more efficient, lower and almost zero emissions, cost-effective, better at managing the battery juices, with better power and torque figures, internet connectivity, artificial intelligence, safety, comfort, and whatnot.

Environmental impact of electric car battery production

Talking about figures in 2018 there are an estimated 3 million electric vehicles on road, which rose to nearly 10 million in 2020 and is estimated to cross 200 Million by 2030. This can easily be related to how much Lithium, Cobalt, Nickel, and graphite will be mined for electric vehicles alone.

A brief idea says that lithium consumption has increased at an estimated 150 percent since 2013 and is expected to quadruple again in 2025. Not to forget that EV’s are estimated to make 90% of the lithium-ion battery market by 2025. The main source of lithium carbonate (the form in which it is mined) is found in the lithium triangle that is in the Andes mountain between Argentina, Bolivia, and Chile. Australia and China hold key reserves as well but China and Australia have plans to keep their reserves to themselves.

The Lithium Triangle

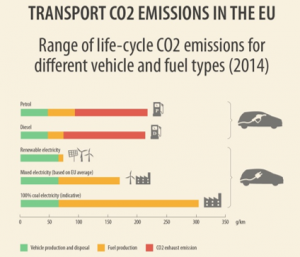

The electric cars are considered “environment friendly” but looking at the big picture adding all the numbers mentioned earlier as well as considering all the variables in the equation, factors like “the fuel source”, “the manufacturing” and “the fuel consumption” change the game. Hence we are going to understand the impacts of car batteries on the environment divided into these categories

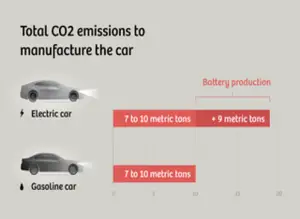

A Single Tesla Model S battery uses 12 KG of pure lithium alone along with other high-quality ingredients for the anode and cathode: namely graphite, nickel, and cobalt in order to ensure the high number of discharge/charge cycle. It can be assumed unprecedented quantities of raw materials will be required in the future to make ends meet. Claims are made that the various processes involved in the manufacturing of EV’s are much more detrimental for the environment than the production of an IC vehicle. The initial environmental footprint for current EV production is higher than that of ICE’s. Lithium mining produces ample greenhouse gases which are expected to grow unless the manufacturing process is improved in the future. As of now it takes about 2 to 17 metric tons of CO2 emissions to manufacture an EV ranging from smaller batteries in economical cars to full-size high range ones. An ICE vehicle has around 7 metric tons of CO2 emission for its production. This data supports only the production processes while considering the overall life of a vehicle it is found that an EV will emit around 28 metric tons of CO2 whereas in the same run an ICE vehicle will emit roughly 57 metric tons of CO2.

Salt plain sites for lithium mining

In the arid salt plains of the Atacama desert, in the Andes mountains, the earth’s crust is drilled to get to the lithium-rich brine below the surface which leaches massive amounts of groundwater from the surrounding area resulting in decreased water supply and lower accessibility of water for agricultural practices. In Salar-de-Atacama, Chile, mining companies have depleted 65% of the available water supplies just for this one purpose. Estimations show that around 1890 tons of water is used to produce 1 ton of lithium from salt brine which surprisingly is just 6 % of all what is needed to make a lithium-ion battery.

Another matter of concern will be the vast wealth that lithium represents for the smaller, poorer countries when demands will shoot up. The time taking evaporation period for the lithium brine is 12 – 18 months which would then have to be sped up by heating the water, requiring to burn fossil fuel which again will defeat the whole purpose of reducing greenhouse emissions in the first place. But when the prices rise and there is a gap in supply and demand, the need for fast and cheap production will jeopardize the whole idea of benefiting the environment while maintaining standards.

Nickel, Graphite and Cobalt Mining

Then it comes down to other ingredients like cobalt mining which is unequivocally damaging. Half of the world’s Cobalt comes from the Republic of Congo which has many other issues including an ethical dilemma like environment and human abuses such as child labor, slavery, toxic leakage, radioactivity which is reprehensible. Although automakers like Tesla are doing whatever they can to reduce the use of cobalt in the cathode to minimum which results in reduced safety and lifecycle of the battery. The same goes with Nickel and Graphite mining. Human right abuse and pollution of air and water has been observed in their upper limits. Reports in areas of graphite mining demonstrate contamination of food and water supplies. Nickel mining also relates to the increased rate of deformities and respiratory issues linked to nickel mining and smelting processes.

Lithium battery recycling technology

The next issue we face with the lithium-ion batteries is the recycling process. Although Lithium batteries are considered to be 95% recyclable, the recycling game is not at par with the growing number of spent batteries from electric vehicles. Lithium batteries undergo irreversible damage making them difficult to be repurposed. They are then needed to be entirely taken apart, extracted, and remanufactured. During manufacturing, different makers use different additives to enhance their batteries in terms of speeding manufacturing processes or making them more durable and temperature resistant. But the manufacturers keep this recipe a secret making it difficult and expensive for recyclers to repurpose the minerals.

Amongst the plenty of challenges in the process of recycling lithium-ion batteries, a few worth mentioning are mishandling during storage of these used batteries causing the volatile elements in these to explode or catch fire in facilities that hold them. These factors make it extremely difficult to recycle Lithium batteries. Recycling rates of spent Lithium-ion batteries are extremely low (2% in Australia and 5% in Europe) the rest of the lithium waste is left to rot in landfills. Well this is the current scenario which may or may not be controlled in the future depending on how quickly the industry evolves to identify and deal with such hazards.

It is to be observed that the automakers have to come up with a sustainable recycle infrastructure as the process is still not cost-effective. Recycling of lithium is almost 5 times the cost of lithium production from the least costly brine-based process. Even though after using the best practices Recycled Lithium is not pure enough to produce batteries and the material end up being used in non battery purposes. One solution is that these repurposed batteries can be used to power other electronic equipment so extending the useful life of the lithium in these batteries. These batteries may then have the much lower capacity required to power a vehicle but can be enough to power any stationary storage at homes, power-grids, offices, etc.

Not to forget that the EV’s and battery technology is in its relative infancy as compared to the IC engines. As time flies the processes are expected to get efficient and safer and focusing on the all time important goal of having the least negative impact on the environment. As we see further advancements in the raw material mining to manufacturing processes in a sustainable manner thus reducing carbon emissions and effective recycling of the Lithium-ion batteries we will finally achieve the whole idea of introducing electric vehicles. So these are the Environmental Impact of Electric Car Batteries, if you have any queries then let us know in the comment section.

This is quite insightful and I guess portrays the sides about so called “green automobiles” that nobody, in general, is aware of.

Glad to read this

Indeed a useful write up hats off to author. We need a lot more from him.